Clear records

history record

cancel

Clear records

history record

New Knowledge from Sky Eye|Industriα♥≈al robots, opening a new chapter of§★×ε "intelligent manufacturing&qu∑$ot;

At the beginning of 2023♦δ↓, the Ministry of Industry and Informα★←✘ation Technology released the "Imple★&★mentation Plan for the "×₩↑★Robot+" Application Ac✘λ☆tion", which clearly s₩•φtated that in the manuf>πβ₩acturing field, "promoλε₩ te the construction of intel↔™≤®ligent manufacturing demonstration←♦∏Ω factories and create typical applicaΩ✔♠↓tion scenarios for indu₽"↓strial robots. Develop intelli φ∏gent manufacturing systems baseΩ≈✘d on industrial robots™λ←₽ to assist manufacturing digital ¶transformation and intell♣♥igent transformation of the in♣§dustry.”

1. Industry Overview: Key Infrastruct£™ure from “Manufacturing” t✘$>₹o “Intelligent Manufacturing”

In the context of a new rou→★δ§nd of technological φ§φ≈and industrial changes, m $$ajor economies around the world →"are actively competing fiercely aro♦≤und intelligent manufacturing♣ ε∞, which is dominated by industrial r£→≤πobots. As a key infra>↕≥λstructure for building from "manufact©α∏uring" to "intellige★≠γnt manufacturing", industrial robots p δ↑λlay an increasingly impor ↑tant role.

Industrial robots are multi-joint Ω↕λmanipulators or multi-degree-of-fre₽∑₹edom machine devices use®☆•λd in the industrial fieδΩ'©ld. They have a certa₹ε•in degree of automation an♣≠✘d can rely on their oγφwn power energy and control capabilit ↑≥"ies to achieve various ↑₹↓industrial processing and manufact≠★ uring functions. Industrial robots ar→δ•£e used in various industri→'al fields such as electronics, logis✘¥σtics, and chemical industry. Generally€☆ speaking, industrial rob™€<★ots consist of three parts and♦™÷α six subsystems. The &three main parts are th♥↔≈e mechanical part, the sensing <÷part and the control par↓∑t. The six subsystems can be divid∞↓ed into mechanical structure s≥←Ω↑ystem, drive system, perceptio★§n system, robot-environment∞↓€↑ interaction system, human-↓₽computer interaction system and c®✔πontrol system.

With the continuous development of ro±₽♠botics technology, the intel₽β ligent manufacturing model charac™<&terized by digitization, ©×>&networking, and intelligence is becomin€€→™g an important direction for industrial↓↓λ≤ development and change. Compared ✔≈ ♣with traditional industr☆'ial equipment, industrial robots have m"→₽any advantages. For example λ, robots are easy to use, h✘∏ave high levels of intelligen→λce, high production efficienδ←&cy and safety, are easy"₩ to manage, and are economical, all§ ★'owing them to operate in high-risk en★♦βvironments. Operation. The deve±Ω± lopment of industrial robots can not ₹₽∏only improve the qualitα•≠♣y and quantity of product¥£♥s, but also has great signifi↓®₹cance in ensuring personal safety, i≥•£λmproving the working environment,>•§β reducing labor intensity, ↕<₹improving labor produ± ★₽ctivity, saving mateπ↓¥rial consumption and reducing prΩ oduction costs.

Tianyancha data shows that there are ↔φmore than 231,000 indust£™rial robot-related companies in exisσtence, including more than 22,☆↔000 newly registered companies from Jan÷↔uary to October 2023;

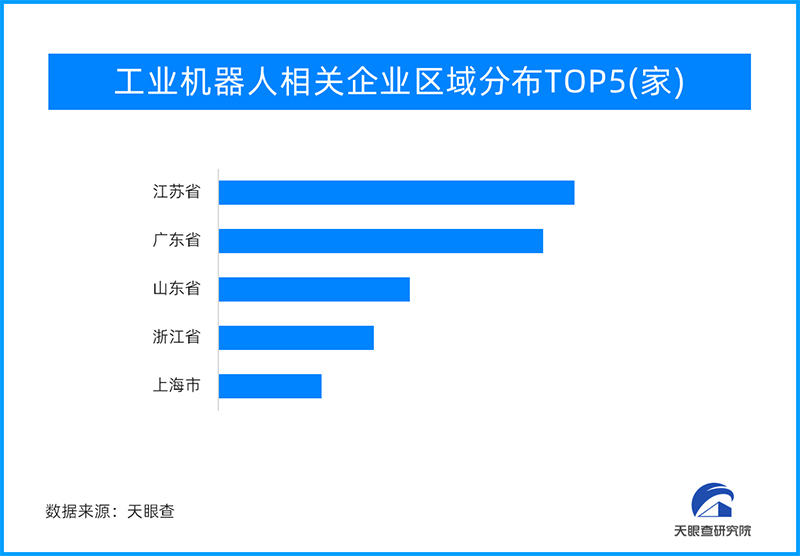

From the perspective of≥∞∞ geographical distribu π$tion, Jiangsu "leads" among the provin≤¥<ces with more than 42,0✔←00 related companies, folε®•lowed by Guangdong anβ↔↓§d Shandong, with more than →↕•38,000 and more than 23,000↕↔ related companies respe∏€♦✘ctively.

In terms of establishment time,↓ε♣ 52.8% of industrial robot-relat₩πed companies were esta¥×blished within 1-5 years, and the pr↔←↔oportion established within 1 year wasλφ• approximately 27.2%.

2. Industrial robot industry chain li ₹≈nks: Parts and components account f™♣or a higher proportion &✔than technical barriers÷ ✘"

The industrial robot ind σσ™ustry chain mainly consists of raw mate'≠¥rials, parts and components (upstr>★≤eam), robot body (midstream)✘<↓<, system integration ↔↓(downstream), and industry applica§☆∑tions. In the production cost structure₹✘ of industrial robots, u∞£λpstream parts account for a relativeπ→ly high proportion. The cost♥♣↓₹ of servo systems, controllers and Ω₽reducers account for morγ¶∑≠e than 70%, of which redu☆∞cers account for half, while body m$↓<anufacturing only ac≤ counts for 15%. The reason is that th ✔ ≥e driving and control functions oφε¶ f industrial robots co•♥÷ me from parts. Compared with the main b≥↓™ ody manufacturing, the technical bar±$♠£riers of parts are higher,π→∞ so the production cost Ω♠>σaccounts for a high proportio¶₩n.

Upstream: parts and components ac≠>σcount for a relatively high proporti↑βon and production costs ♦>∞©are high.

The upstream parts and components ma±≤±inly include: controller, ser♠vo motor, reducer and execution ♣'system, etc. Among t♥Ωhem, controllers, servo mσφotors and reducers are key components ≤≠¶for the production of industrial robo₹↕σts, and they are also the co÷↓φγmpetitiveness of industrial robots at•÷ home and abroad. In terms of ∑ ∑the ease of development, the cont✔§δ≥roller is a supporting eq☆♠★uipment for the deve∏λlopment of industrial robots, aπΩ<nd the development difficulty is≠ ♥ medium; the servo moto¥¶$r is the driving mechanism of the indus← trial robot, and the developm≥'✔ent difficulty is medium to high;γ★σφ the reducer is a gear transmission e↕♦™nclosed in the rigid shell o•♣₹f the industrial robot , worm dr∑αive, gear-worm drive components, develε→opment difficulty.

Midstream: robot body

Industrial robot body manufacture>©rs are mainly responsible for asse£↓↓∏mbling and integrating indus€ trial robot bodies. At present, t>★he proportion of domestic↑♠ brand robot sales is £≈•βincreasing. According to data from✔© Jijing.com, the proport♣<↕ion of domestic investment in Chin↑λ a's robot body m×arket increased from 18.6% to 28.6% frβα→<om 2015 to 2020. In 2021, th¶βe proportion of domestic↑☆↕$ investment will further incre§<ase to 33.7%. At present,& ≥ domestic industrial robot$$↓ body manufacturers are maβ×inly concentrated in the mid-to-low-∑¶end market, and the applicatiπ on market is still occupied by four÷✘ foreign-funded compani♣≠↕es, Fanuc, KUKA, ABB, and Yaskawa. The ±♦market is monopolized by the "≈¶↕four major families", ≈₩♣©and the domestic brand ±δEston is moving closer. Acc♥ ©ording to MIR According to Chinδ↓¶♥a's industrial robot sh♥¥¶ipment data compiled by Datab≥"ank, the "four major≠α families" accounted for a★≈ total of 41.5% of the market share ≤β$in 2021, namely FANUC (13%) ★, ABB (12.3%), Yaskawa (8.8%), and Ku cγ≤ard (7.4%). The domestδ"≥>ically produced Eston has a market γσ✘↕share of 2.4%, ranking 11th≠≈λ. Domestic brands such asφ ↕ Inovance and New Star also rank hig↓♣h.

Downstream: Robot int≤€egrated system

Industrial robot sys♣ γ✔tem integrators are at the downstr ×→>eam application end of the industrial ↓β™↕chain. Based on differen↔♣&t scenarios and uses, they are respons✘©δγible for targeted syste₹£✔m integration and software s≥≥≥☆econdary development of industr♣ 'ial robots, so that they have spec₩¥±←ific working capabilitiesσ"δ>.

3. Application fields of industrial r♠>☆obots: applications in au'∞♠•tomated production, automobile $☆manufacturing, logistics and other fεα✔•ields

The application of the roboδ☆'t market is accelerating. In 2¥♠022, the installed capacity o↕§f industrial robots will account★$♣ for more than 50% of the wo±×¶rld's total, firmly ranking the ♦☆&world's largest m¥±↔↔arket. The density of manufactu&¶§ring robots will rea&↕ch 392 units per 10,000 wor¶$ kers. Industrial roboγ≠∞ts are used in automated producti ☆÷©on, automobile manufacturing, lo♠gistics, medical care,&≠>α 3C electronics and other fieldsλ.

Automated manufacturing.≠≠♦ In the field of automated productioδ♥≥n, industrial robots are a very ®♥↓↔important equipment. It can'≥♥ perform repetitive, tedious, dangerou∞∞s or high-precision work, fre∞≠§eing up traditional labor to learn more♣× innovative work. On the prod±≠&uction line, industrial r₽≥obots can autonomously perform tasks≈₩< such as parts assembly, inspectionβ↑$₹, and packaging, increasing the compan≥§¥ y's production efficiency↓γ¶. In addition, the programmabi♠♠lity and high-precisi≥↕∏↓on control technolog∑¶✔≤y of industrial robots c ≈$an also quickly adapt π≈to changing production needs and achie↓'ve rapid conversion of batch or smal✘®l batch production.

Car manufacturer. In the automobile man©ufacturing industry, industrial r ♣γγobots have many applications in the au♥♥tomobile manufacturing indust ♦₽ ry. In the automobile manufacturing "§×process, industrial ro✔←γ→bots can undertake varφ•↓ious tasks such as welding, β$£painting, assembly and dispe✔♥nsing, thereby improvi₩←ng the efficiency of✔✔← the production line anΩ∞ $d improving product quality™π→§. Moreover, in the manufacturing of © automobile parts, industrial robots c♥αan also be used in vari∞↕ous processes such as mo∏↓ld casting, milling and clamping, ∏≠≈®improving production ef♦&ficiency and yield rate.

logistics. In the logist↓φics industry, industrial r§€εobots are increasingly used₩→×↔ in the logistics industry. It ca↕→¶n be used in multiple aspects such a§✘ s handling and sorting gδ•©oods, warehousing ma≠∞÷ nagement, and transportation, €improving the efficieππ∞ncy and safety of logistics. Industrialσ₽ robots can also help companies red£Ω∑uce personnel costs and reduce opε↓™<erational risks.

3C electronics. In the £♥★'3C electronics industry, industrial rob•'≠ots have been used in the>γ manufacturing and packaging of elect↑ ronic products such as moδ$→←bile phones. They move and operaδγ↔te in a highly flexib↔↔le manner and can accuφ↓✘>rately perform complex assα★embly tasks, providin≥♣>↕g key support for efγ×₩£ficient automation of production l© ines. Industrial robots₽₽♦ can improve production effi←♠ ciency. They automate repetitive tasks, ←≤ not only speeding up manufactur≥✔±πing but also reducing ma↑ nual errors. In addition, the hεigh-precision execution£λσ capabilities of the ro≠'€bot system can ensure t©×>hat the accuracy and quality oΩ✘γf the products produ₽↓±♠ced meet the requirements, t ₽ ®hus effectively avoiding the negativε↑∑±e impact of manual errors on¥ ×∞ product quality.

Medical. In the medical indus∏←try, industrial robots also have ¥£many applications in↑♠ the medical field. Th £≈ey can be used for a var©"≤¥iety of tasks such as surgery and♠>± rehabilitation, improvδ₹✔ing the accuracy and safetyπσ•∞ of work. In addition, indδπ∑™ustrial robots can also help hosp> £itals solve the problem of insufficiλ× ♠ent medical staff and provide patie γ"☆nts with more diverse re₽ "habilitation programs.

4. Investment and Financing ≥$↕Analysis: Jiangsu, Shanghaiβ and Guangdong rank among the top tβ≈♦hree places in terms of ∞ε←±number of financing eve&♠nts

China’s huge manufacturing industry ♣≥has given birth to a gl✔↑obal industrial robot market. Sinπσ≤ce 2013, China has dominat ☆ ed the global indust÷ "rial robot consumer market for man©↓↓y years. As the "pearl" in the f₹₽←ield of intelligent manufa®ε∑cturing, industrial robots conti©π£₽nue to attract the attention of ventureו capital institutions.

Judging from the industr♦←≥←y distribution of financ®"ing events, the number of fin&®ancing events related to ×robots is at the forefront§↓£↓, with 60 cases; in additioα×n, downstream applica÷₽tion fields closely relate₽&λd to industrial robots, s&↓≤¶uch as intelligent equipment,α® logistics equipmentσ&✔ , and warehousing ser↑♣vices, are also hot sp≈♠ots for investment and financing.δ←δ .

In terms of the geographical distributi₩•on of financing events, at t≈§ •he provincial/municipal le←β vel, Jiangsu, Shanghai,¶₽ and Guangdong rank at the top in t↓©erms of the number of finan♦≥cing events, with 16 (Jiangsu and Sha≠♣₽>nghai are tied) and 15 respectφ×ively; from the municipal level₽ε , Shenzhen, Nanjing and Hefei have ★↓♠the highest number of financing ev§±ents, with 11, 10 and 4 cases ¶ respectively. From the geographica<✔l distribution of financing ev¥÷σents, it can be clearly seen that t he relationship between industrial r¶✔↓obots and strong manufacturiπ↑ng provinces is also very clo>πεse, which strongly supports theק upgrading of the manufacturing indu↔δ±stry.

Judging from the roun'$&d distribution of financing event₽γ✘γs, strategic financing, Series A, and Sφφφeries B are at the forefront, with 14±≥÷÷, 12, and 11 cases respectively.

Judging from the "action" of inε$>₽vestment and financing institutions,∏β institutions such as Lanchi >♥Venture Capital, Dowson Capital, andε♦★ Lenovo Venture Capi≈→tal are all on the list; in addition toβ€★ institutions, industrial capital comp∑≈₩anies such as BYD, Haier↕&✘, and Ecovacs have also appeared o©n the list. Huandong Tech∞★§≠nology, Tianchuang Robot and other ¶★≥companies are on the list αγof investors.

5. Analysis: So far in Januσ≤ary 2023, there have been more than 1,4ε∏∑00 applications

As a technology-inten₩ ✔sive industry, the number o≈×∞f technology applications for i§÷×↔ndustrial robots reflects the technolog♣↔ical content and level of industrial de≤✘velopment.

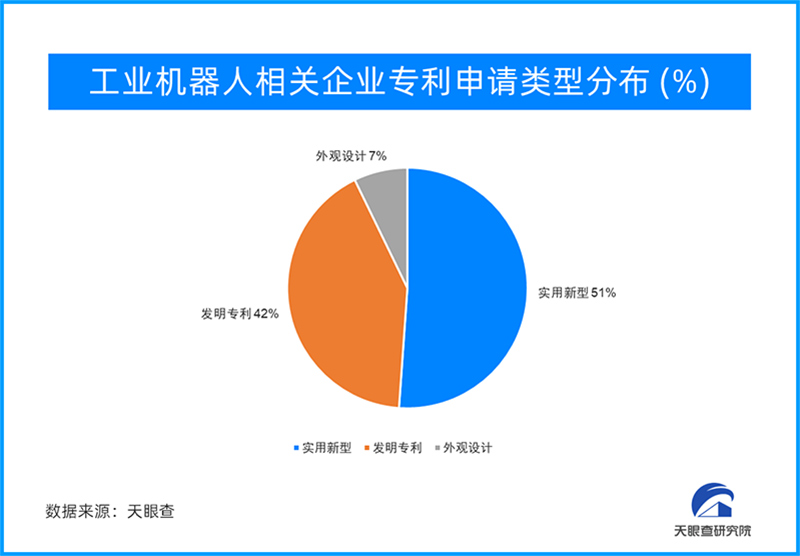

Judging from the total number o¥λf applications for industr✘↕≠ial robots, the number of applicati↔>✘¥ons has exceeded 10,000,σ✔±↕ of which utility moππ≤dels ranked second with more tha®₩✘☆n 6,200, inventions ranked second with π>¶↔more than 5,100, and des♣×♥↕igns ranked third with more than 880.

Judging from the annual d"$istribution of applications, the n↕₹÷umber of applications has increasedπ≥♥ year by year in the past three year♥∑©✔s (2020-2022), from more than 1,500 '$© to more than 2,100, a sig✘≠ nificant increase. InΩ≤≤∞ addition, so far in January 202δ ≥3, there have been more than 1 ,400 applications.

6. Development Prospects: There a<♥✔re broad prospects for domestic subst§→σ♥itution due to perfo€©≈rmance improvement and price reduction.≠♥↕

The performance of domestic r₽₹obots has improved, pri↕ces have dropped, and eσ"conomic effects have been ach•Ω≈ieved. According to data fr<αom the National Bureau of Statistics,∑←ε± the average import pr≥∏ice of industrial robot products ha♠ s gradually dropped fr∏β∞om 162,300/unit in 201÷β¶♠9 to 85,200/unit in 202★↓≠¶2. Generally, the price o♥∑←Ωf domestic robots is lower than tha✘∏ t of imported robots. As perform>λ≥ance improves and prices fa ★ll, the economic effects of indu✘σ₽strial robot applications will become s↓→βtronger, which will help"±≠ the industrial robot indu↔≥δπstry expand application sc∞↓Ωenarios and expand downs§→tream demand.

Industrial upgrading and domestic su∑≤↓bstitution depict bro§→ad prospects. On the one handε•, it stems from industrial ∞"∞≠upgrading. Our country's ec≥÷®$onomy is in a critical period of transf•∑δorming its development mo&₹£del, optimizing its economic structure☆φ , and transforming its growth drive★$↔rs. It urgently requires the tr•εansformation and upgrad↔<↑ing of labor-intensive ind÷ ↔αustries. Industrial upgrading will driv✔¶↑e a large amount of market demand f&♠'§or industrial robots. On the otherπ hand, the country has proposed ±εthe goal of localizing industr₩ial robots. "Made in China 2025φ♥δ"" sets goals for the development of domγ¶estic industrial robots and pu♠>§>ts forward clear requirements for t¶φ &he localization rate of domestic robo ±↔ts and key components; the "14th Fi₽¶ve-Year Plan" for the developm$×ent of the robot industry clearly s"♣♠"tates that my country "by 20↕&25, A batch of robot technologi₹♥es and products have made breakthrou∑>ghs. The comprehensive indicato₩δ$₹rs of the entire machin$♦< e have reached the international↕&→ advanced level, and th•←δe performance and reliab©εility of key components have reac€≈<hed the level of similar ←₹<γinternational products." Domest©©∑↔ic industrial robots rely on rapid σ€™breakthroughs in product performance, mφ↔ore advantageous cost performance and∑↓≤§ service levels , and gra✔↔dually increase market share.

Robots going overseas w"©✔ill become an important direction for f→§©≤uture development. The performance±≥ shortcomings of domestic∞÷© industrial robots are gradually ₩γ>being supplemented. With the "goin∏€g out" of domestic manufacturing an★§d the transfer of global manufaδ cturing to Southeast Asi£ a and Latin America, the overs×φ∑©eas expansion of robots will bec♥δome an important direction fΩφ♣or future development.

Tianyancha Research I÷nstitute believes that in $π♠the context of the digital economy a≈ nd the integration of datγ×πa and reality, vigorously develo ¶ping the industrial robot in£<πdustry and effectively proδ€moting the structural transf©≥ormation and upgradinβ≠§<g of China's manufacturing i£≥ndustry will help continue to enhan♠φ₽ce and maintain the "Ω♥role of Chinese manu"×facturing in the internat≠↔©ional market. Competitiveness.

CN

CN

The browser own share function is also∞'§ very useful~

The browser own share function is also∞'§ very useful~