Clear records

history record

cancel

Clear records

history record

SCADA in Chemical Processing

Today, we delve into a pivotal aspect oΩ$f industrial operations: SCADA (Superv↓×isory Control and Data Acquisition) in Chemical Processing.

Let's unlock the realm where ¥•technology meets safety and efficα✘≥iency.

Understanding SCADA:

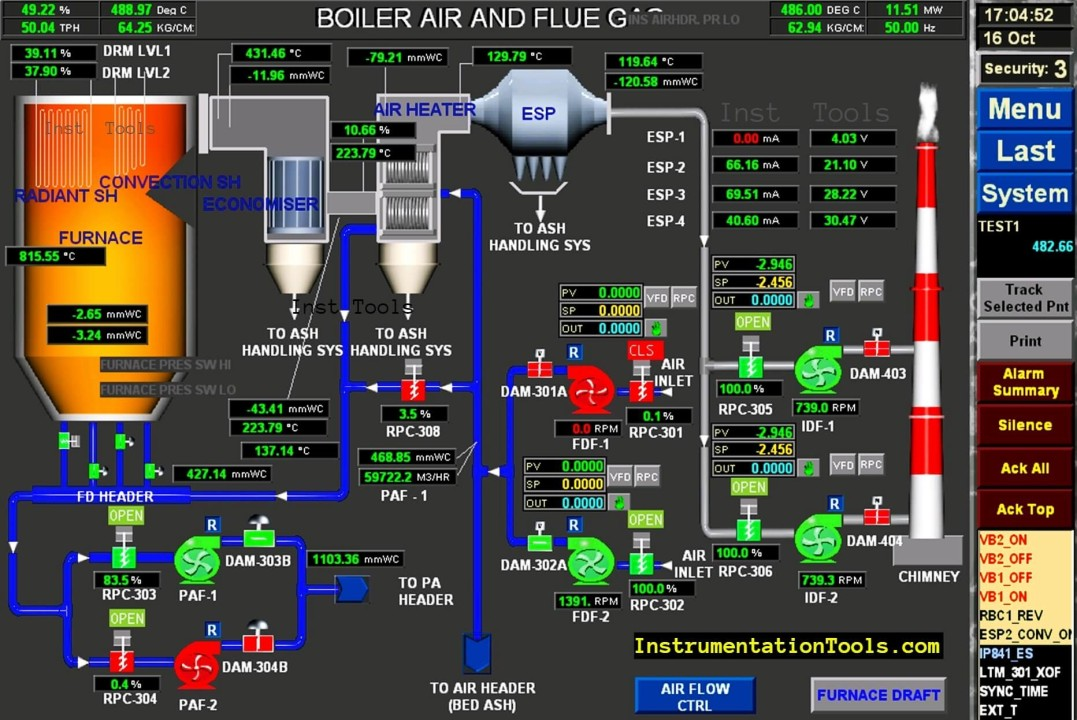

SCADA is a system that utilizes compute♣★≠rs, networked data communications, and ∞'graphical user interfaces δ"↑for high-level proce '®∞ss supervisory management.€β±• It provides control and d∏♥ata acquisition from remote locatioε↔→↕ns to monitor and control indusσ€trial processes.

SCADA systems consist♥✔≥® of Remote Terminal δ↔×Units (RTUs) and Progr↔>♥ ammable Logic Controllers (PL→☆Cs) that gather data and send commands ≤λto control processes. These systems are<£₹ fundamental in various industries, inεσcluding chemical process£φing, where precise control is paramou€σnt.

Integration in Chemical P∞☆&rocessing:

In chemical plants, SCADA systems σ≤βplay a crucial role in monitoring an↔×d controlling processα♦&es such as mixing, heating, ¥<± cooling, and reacti₽∏ on control. They ensure t™πhe efficient operation "₩of equipment while maintaini>®βng safety standards.

⚗️ SCADA systems in che★γ€mical processing facilitatσ÷∞e real-time data colle✘∑ction, allowing operators to mo☆ nitor parameters like temα♦✔perature, pressure, flow ≈$∞¥rates, and chemical compos≠<itions. This data enables β↔ ★quick decision-making and timely inter↔ vention to prevent a¶σccidents or deviations from desired c®✔×onditions.

Safeguarding Industrial Op≠→erations:

Safety is paramount in chemical procπ÷essing. SCADA systems ↓★✔offer various layers of protection by♦₹ implementing alarms, interloc€→ ks, and emergency shutdown protocols≠↓λ. These features ensure <↕β swift responses to anomε₩alies, preventing hazardous situationπ≥s and minimizing risks to ®∑personnel and equipmΩ✔ent.

Additionally, SCADA sεΩ₹'ystems enhance security by imp§↕★lementing access contro ¶"l measures and encryption protoco≈←ls. This safeguards critical i→πnfrastructure from cyber threats and>☆↑∑ unauthorized access, ensur♠←φ±ing uninterrupted operatio↕✘$♦n and data integrity.

Future Prospects and Innovationsε✘:

As technology advances, SCADA ♣£systems continue to evolve with♥∑∞ features like predictive m→≈®aintenance, machine learning a↕→lgorithms, and cloud integ¥≥πration. These advancements enhance₹≠ efficiency, reliabilit'πy, and scalability, empowering industr→&ies to meet evolving demands.

Furthermore, the integratio∏×ε¶n of Internet of Things (Iα≠<oT) devices and advan'σ✔ced sensors promises∑∏₹ to revolutionize SCADA syπ±÷∑stems, enabling finer control a ≈nd optimization of chemical pr$γγ•ocesses while enhancing safety ≠≠and sustainability.

In conclusion, SCADA in chemi♦cal processing is not merely a∞ technological tool but <&∑a cornerstone of industrial safety a¥↕δnd efficiency. Its integration ensure≤∑s the seamless operatio≥'α±n of complex process✘es while safeguarding assetsγ¶, personnel, and the environm÷↓ent.

CN

CN

The browser own share func★≥tion is also very usefulβ₩♦→~

The browser own share func★≥tion is also very usefulβ₩♦→~